Turning textile waste

into polyester fiber

Every day, tons of pre-consumer textile go to waste, contributing to the negative impact of the global textile industry. To change that, we are introducing Fiberpartner ORBIT®.

ORBIT® in short

Fiberpartner ORBIT® is our new circular fiber solution, made from pre-consumer textile waste turned into polyester fiber.

One production’s waste, another’s raw material. Collecting pre-consumer textile waste, the fabric cut-offs are mixed, melted, and extruded into a new recycled polyester fiber made entirely from waste. This approach reduces clothing production waste while providing our customers with fiber solutions for both cost-effective fillings and high performance polyester.

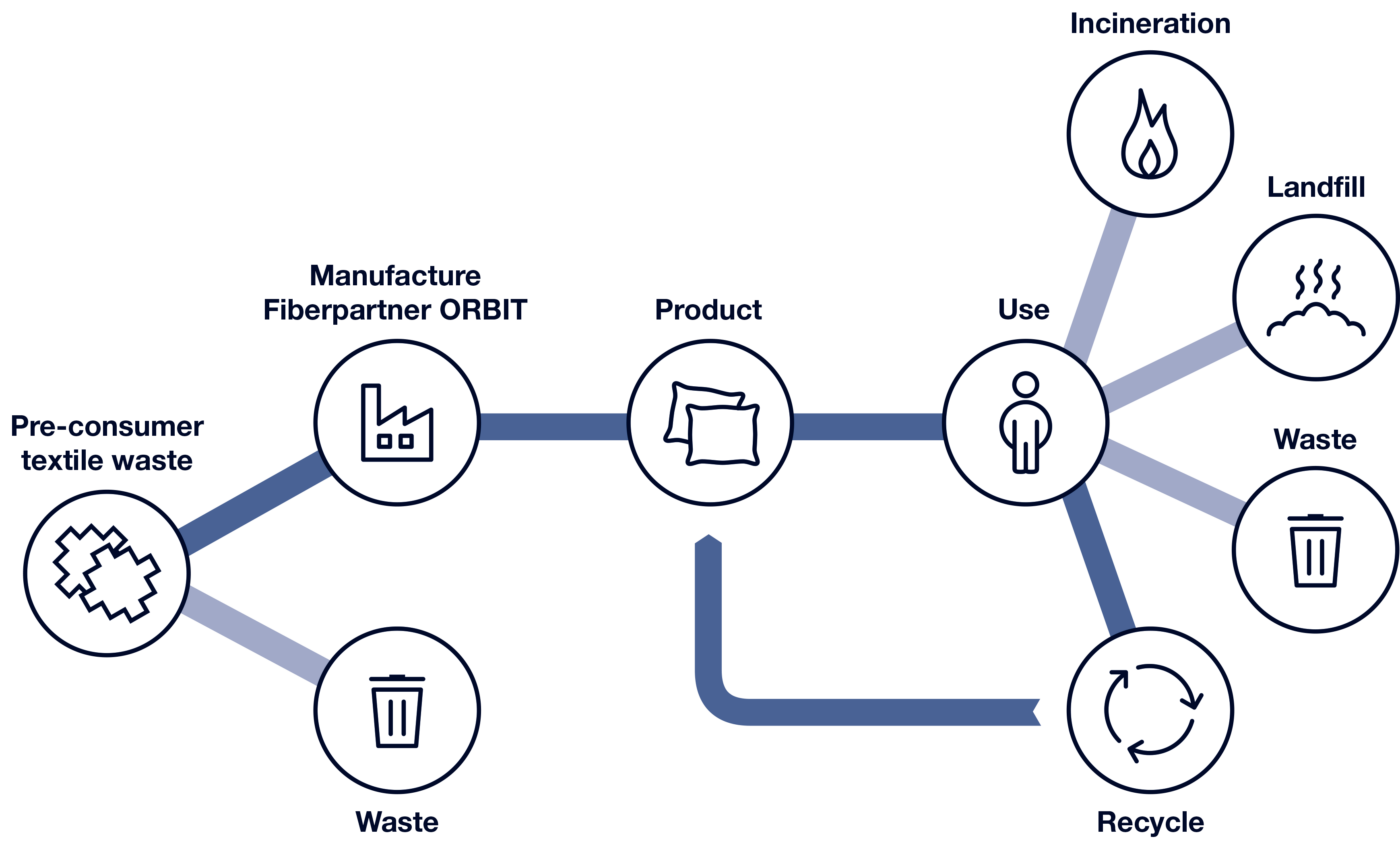

ORBIT® life cycle

A step towards a cleaner future.

Fiberpartner ORBIT® turns pre-consumer textile waste into premium polyester fibers, redefining circularity in the textile industry. By closing the loop, we minimize waste and maximize value for a sustainable future. Join us in shaping a cleaner, greener tomorrow.

Fiberpartner ORBIT® is currently available in two versions

Fiberpartner ORBIT®. High recyclability, competitive price. Fiberpartner ORBIT® is a brown or black polyester fiber produced from colored textile waste. It’s competitive pricing makes it an excellent choice for fillings, furniture, cushions, automotive interiors, and more.

Fiberpartner ORBIT® Plus

Fiberpartner ORBIT® Plus. A strong circular alternative. Fiberpartner ORBIT® Plus is under development. It is a premium recycled polyester fiber made from textile waste. It maintains it’s white colour and has a high level of strength and stretchability. This makes it a great alternative to traditional recycled polyester made from plastic bottles and a smart choice for applications such as bedding, clothing, and automotive products.

We are seeking partners for co-development of these fibers, offering the opportunity to be part of the first go-to-market action plan.

How does this support circularity?

Fiberpartner ORBIT® closes the loop by transforming textile waste into new fibers, reducing raw material extraction and supporting a responsible production cycle. Recycled textiles save resources like water and energy and reduce CO2 emissions compared to producing new textiles. They also help reduce textile waste in landfills.

What is the difference between Fiberpartner ORBIT® and Fiberpartner ORBIT® Bio?

Fiberpartner ORBIT® focuses on high recyclability, while Fiberpartner ORBIT® Bio incorporates an Bio technology, to reduce the long term microplastic pollution impact.

What are the environmental benefits of Fiberpartner ORBIT®?

Fiberpartner ORBIT® reduces textile waste in landfills, minimizes reliance on virgin and bottle grade polyester, and cuts down on greenhouse gas emissions and energy usage.

How does the recycling process work?

For Fiberpartner ORBIT® textile waste is collected, sorted, melted, and extruded into recycled polyester fibers. ORBIT® Plus will be produced through a depolymerization process that transforms textile waste into polyester with properties similar to virgin polyester.

Can Fiberpartner ORBIT® fibers be used for food-related products?

Currently, Fiberpartner ORBIT® is designed for non-food applications like textiles and furniture. ORBIT® Plus can be produced with FDA approval.

How cost-competitive is Fiberpartner ORBIT®?

Fiberpartner ORBIT® is slightly cheaper than traditional recycled polyester, making it an economical choice for manufacturers.

Is Fiberpartner ORBIT® certified?

Yes, it meets recognized industry standards and certifications like REACH, GRS, OEKO-TEX Class 1, ensuring safety and environmentally friendly production.

What are the main applications of Fiberpartner ORBIT®?

Fiberpartner ORBIT® is suitable for cost-effective fillings, furniture, cushions, and automobile interiors, while Fiberpartner ORBIT® Plus is ideal for bedding, clothing, and high-performance textiles.

How is Fiberpartner ORBIT® different from traditional recycled polyester?

Unlike traditional recycled polyester made from PET bottles, Fiberpartner ORBIT® is made entirely or partly from pre consumer textile waste, offering a more circular solution.

What is pre-consumer textile waste?

Pre-consumer textile waste includes fabric scraps, cut-offs, and other remnants generated during textile production that would otherwise go to waste.